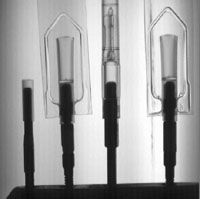

Bag Inspection

Particules, tube position and size, shapes

Inspection of pharmaceutical plastic bags is a challenge due to low contrast matter and specular reflexion. This system performs quality controls on rotary machines as well as standard linear machine (Kiefel Type).

Cameras verify presence and positioning of components, and check seal quality as well as presence of particles. Goals being to avoid presence of microscopic cracks, or contamination areas which can appear catastrophic during bags filling.

Microscopic cracks can cause bags blowing during filling and/or centrifugation. This type of incident can take a dramatic connotation in countries where blood is regarded as sacred (Japan).

Our system who is in operation since 1998 was an unique implementation with avant-garde technology of frame grabbing and edge detection with variable models. This system can be extended to verify plastic bottles.

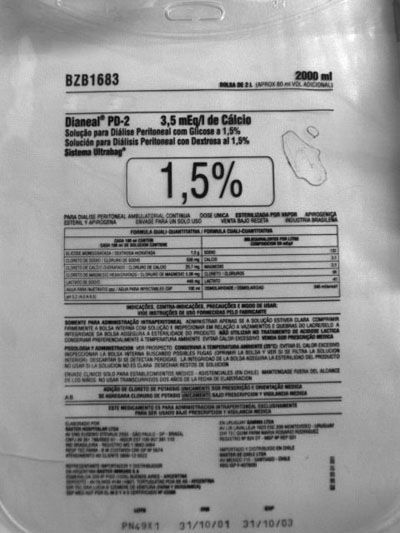

Another quality control task could be implemented by controlling bags labels by using a unique technique of image acquisition on a specific conveyor.

This insures that the correct label is stamped on the correct bag.

Image acquisition on the fly

All images are recorded at each cycle, for further processing while the new cycle is coming.